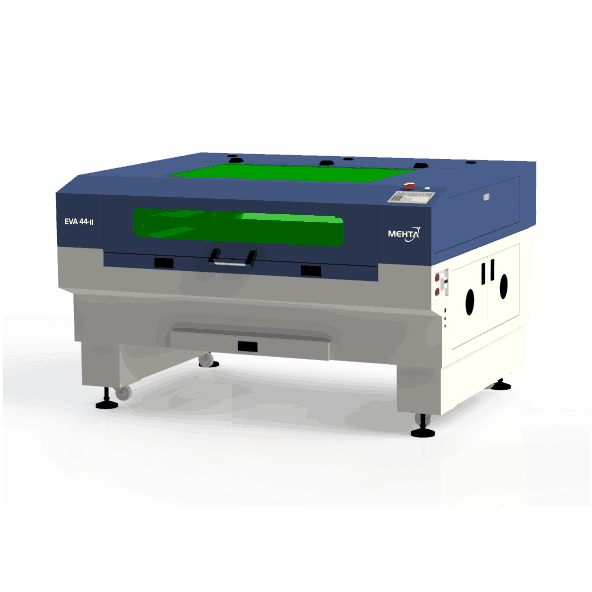

E-WELD Shield

Art.-Nr : D01116

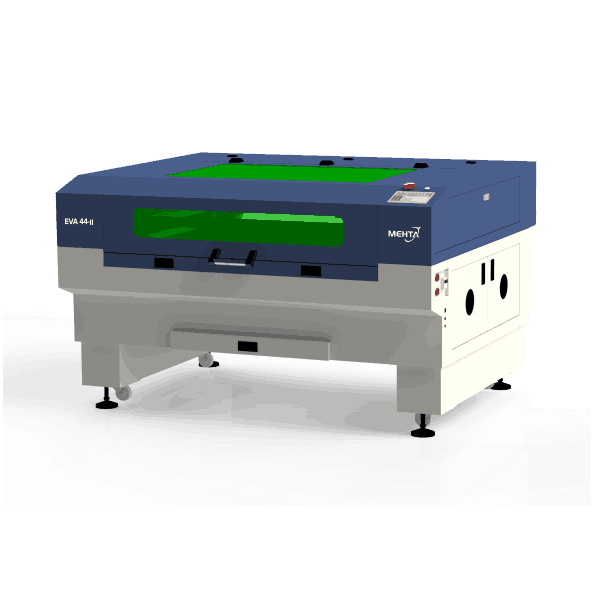

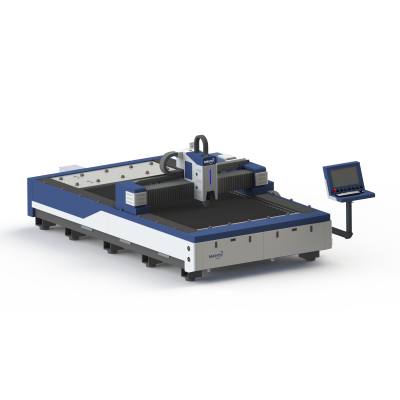

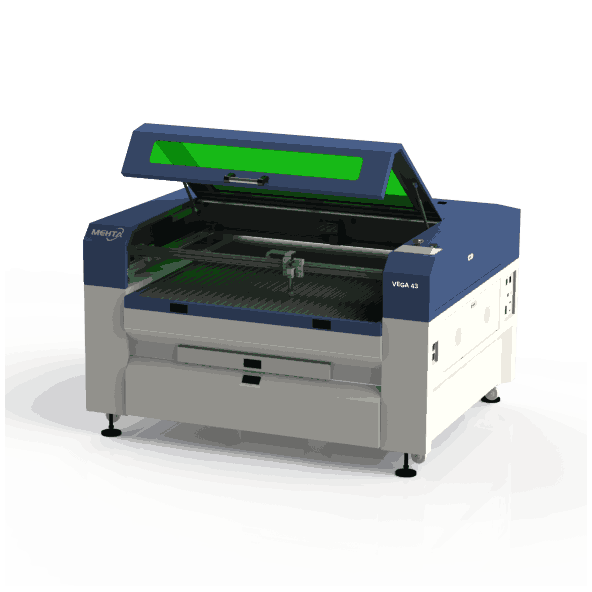

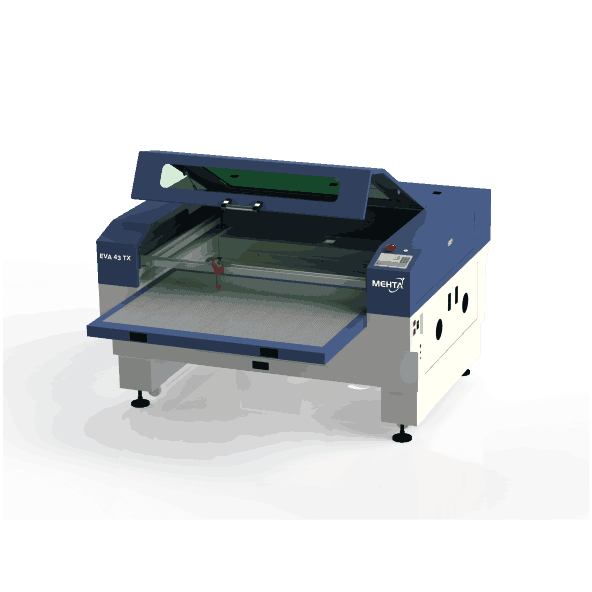

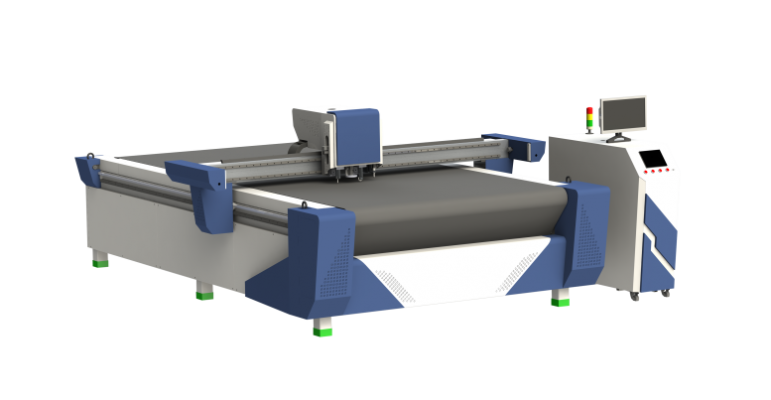

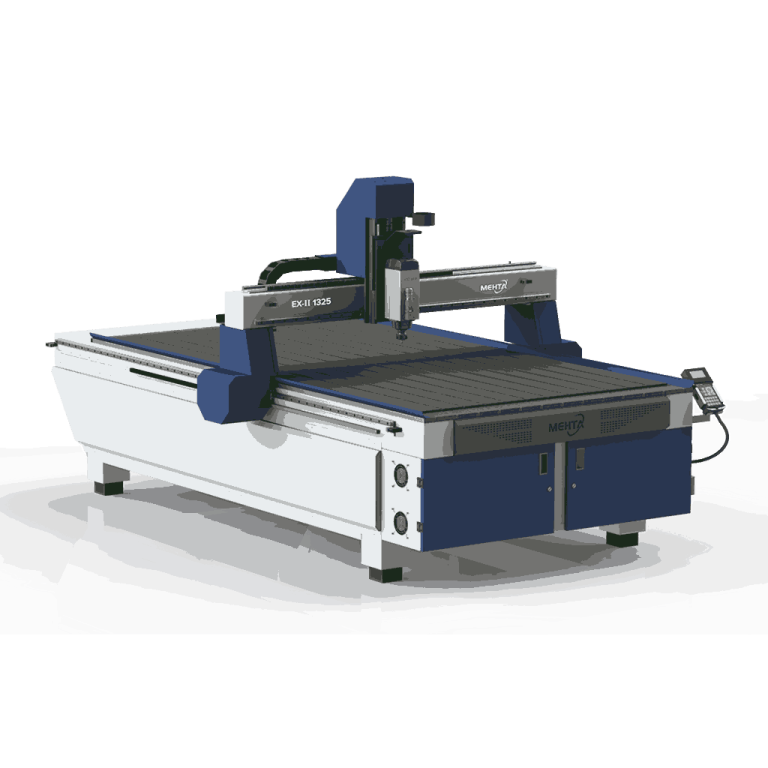

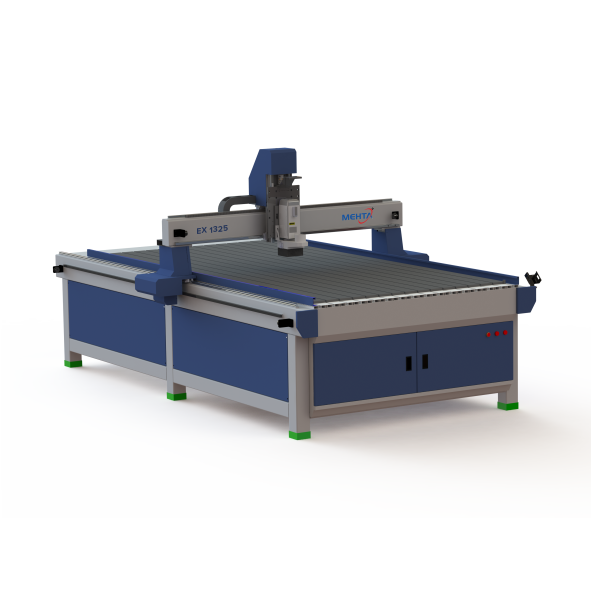

Surface protection for plasma- and laser-cutting machines – Coating the bars for the workpieces to be cut prevents major build-ups of slag that is a by-product of cutting. Using E-WELD Shield makes the bars faster to clean, and they can be used for a longer time. This facilitates neat, time- and cost-effective work processes. By means of the spray system, E-WELD Shield is applied in an optimal way, achieving effective protection.

- Prevents major build-ups of slag on the bars during plasma- and laser-cutting

- Time savings: slag is easy to remove.

- Improved cutting results: The cut-outs of the plasma- and laser-cutting machines rest flat on the cutting benches

- Excl. spray system (available in the E-WELD Shield Package)

E-WELD Shield is used in the field of plasma- and laser-cutting. It is easy to apply by means of the spray system and provides optimal surface protection. By coating the cutting benches, the ceramic additives contained in the product prevent major slag build-ups. At the same time, this slag is easier to remove, which means that cleaning the bars requires less time, making the system available for longer periods of time. In addition, costs are saved because the bars do not have to be replaced so often. The work pieces to be cut rest flat on the bars, which increases the quality of the cutting results.

- Faster cleaning and longer use of the bars

- Contains ceramic additives that prevent slag from building up

- Economical: 1 kg of E-WELD Shield is usually sufficient for approx. 20 square metres

- No labelling required under the CLP Regulation

Related links to "E-WELD Shield"

- Do you have any questions concerning this product?

- Further products by E-WELD Shield

Technical specification

| Label: | label-free |

| Mechanics: | manual cleaning |

| Seal of approval: | Ready-To-Use, unlabelled, VOC reduced! |

| Safety advice: | Aquatic Chronic 3 |

Field of application

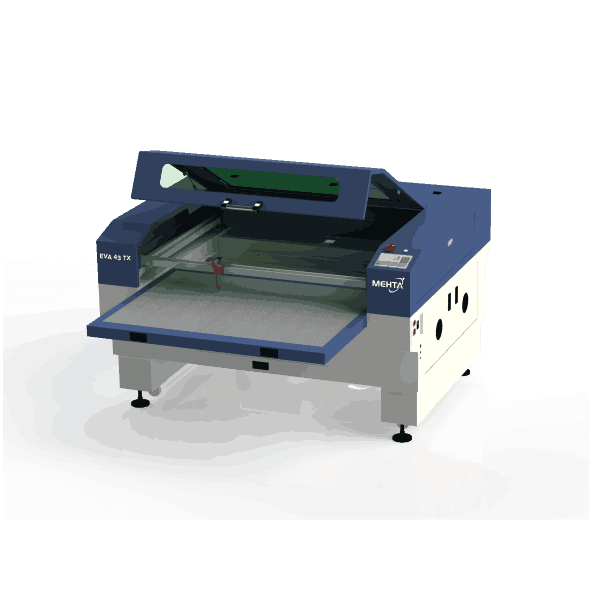

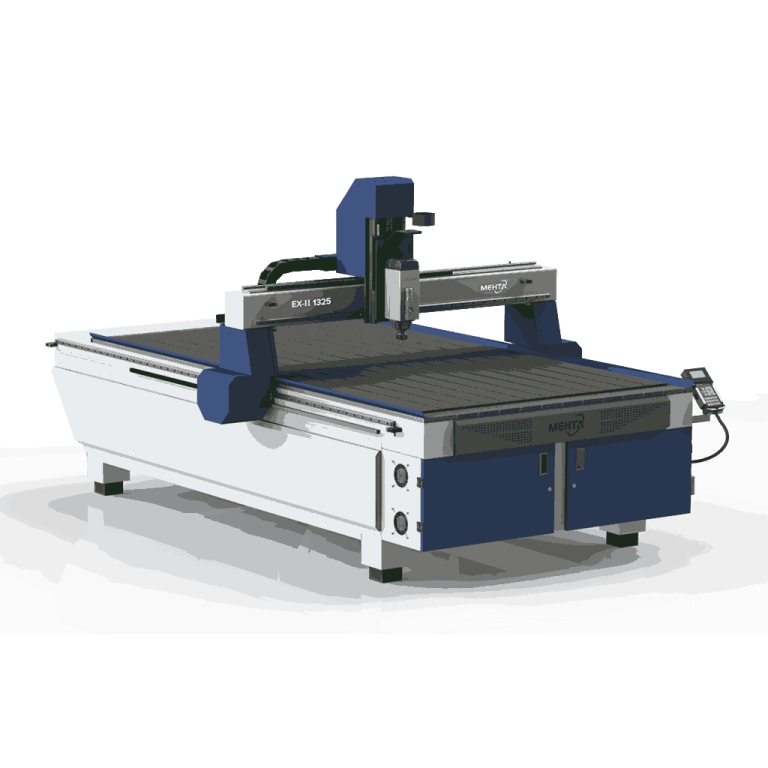

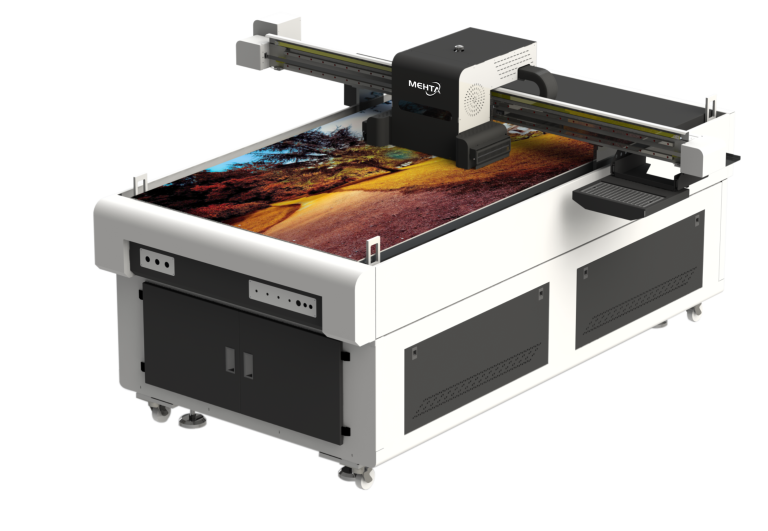

Coating for plasma- and laser-cutting benches

Usage

Mix the E-WELD Shield thoroughly before use, then apply a well-covering layer of E-WELD Shield to the new or cleaned bars; ideally repeat the process. Allow to dry for approx. 1 hour. Eliminate the slag after approx. 4 weeks, and apply a new layer of E-WELD Shield. 1 kg of E-WELD Shield is usually sufficient for approx. 20 square metres.

...

...

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent

PPick Up at our Shop/ stock in Riga:

Brīvibas gatve 204a ( entrance from Turaidas 2c)

Riga, LV-1039

Latvia

Standard Delivery:

Omniva Delivered within 2 - 5 days.

DPD

Express 1-2 Day Delivery *ask to manager

Next Day Delivery *ask to manager

Next Day Evening Delivery *ask to manager

Unlimited Delivery (VIP)

Sign up for VIP exclusive Free Delivery on all orders through the app for the whole year. Wanna unlock ALL the most exclusive VIP Benefits? *ask to manager

-------------------------------------------------

See DELIVERY Terms at: Delivery