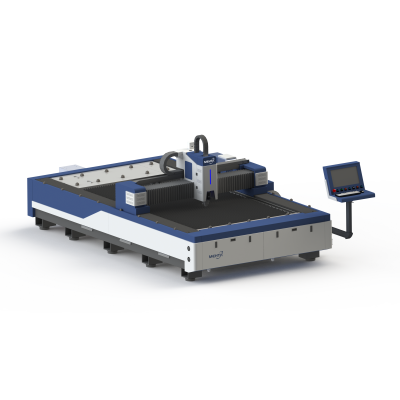

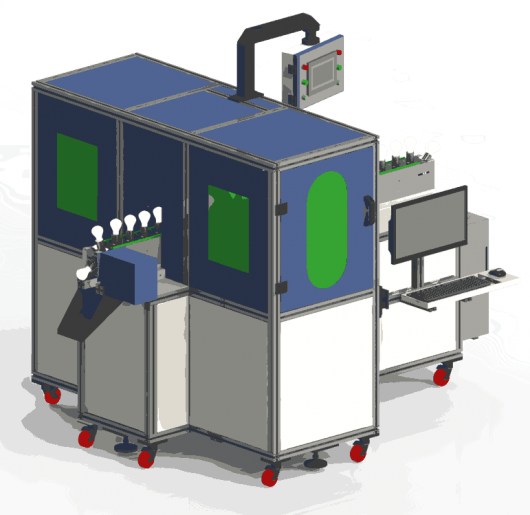

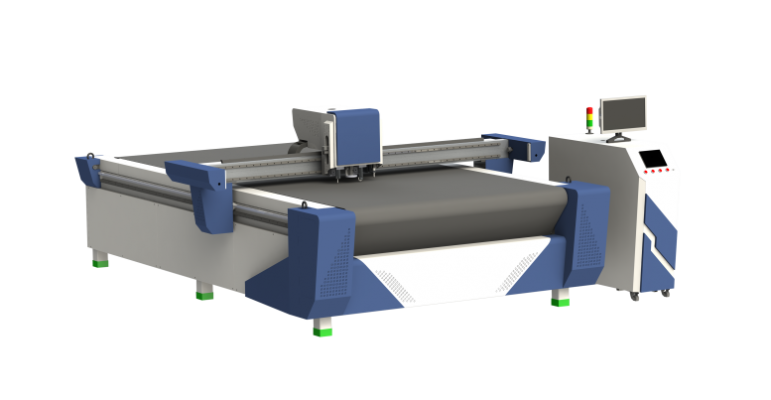

Sleeve Master Auto HANDS FREE AUTOMATED SLEEVE MOUNTING

Based on the Ultra Reliable Camis Principle, The Sleeve Master Auto is a high quality machine that’s very quick and easy to use; always providing you with Press Ready sleeves, automatically. Simplicity is the key with the SMA and its features have been designed for minimal skill, while improving on the overall standardisation of the various functions:

REGISTER MARK ACQUISITION SYSTEM

Suitable for crosses and micro dots.

DOUBLE DECKER CAMERA SYSTEMS

Allows the register marks to be presented at to the cameras whilst checking and controlling plate position and verifying zero skew.

PLATE “ANTI CURL” SYSTEM

Allows used, demounted and most curled plates to be used as easy as new flat plates.

PLATE SUPPORT TABLE

Allows the operator to position the plates flat and with ease finding the registration marks quickly.

AUTOMATIC PLATE POSITIONING

The manipulation system handles the plate until the exact mounting position is reached, automatically.

AUTOMATIC PLATE APPLICATION SYSTEM

The full width plate application roller presses the plate on to the print cylinder with standard bond strength and removing air bubbles and stretching.

TS3.0 & "No Scratch" TAPE CUTTER

The new Taper-Slide tape application system redesigned by Camis applies tape perfectly with no air bubbles & non scratch tape cutting, all combine to offer an even more ergonomic and practical solution to tape application. Turret allow's quick change between densities. Even allows the operator to apply tape cross ways with roller application. The SMA is the reliable and practical solution for a fully automatic tape and plate mounting system. SMA Total Work Flow Control Automatically.

SLEEVE MASTER AUTO 900

An advanced Automatic “sleeve change” Flexographic plate mounting system.

Advantages

- Eliminates waste associated with manual operations, reducing operators stress

- Ergonomic and easy to master

- Raise the level of standardization in the mounting department, shift after shift, reducing the risk of waste and claims

- Constant and monitored mounting times for optimal cost control

- Camis Reliability and Repeatability as standard.

- Flexo Industry 4.0 data acquisition system provides rapid job change

Print width

- From 900 to 2000

- Other measures on request

Print development

- From 300 to 1300

- Other measures on request

Mmrm vision software

Automatic detection of mounting references and advanced reporting functions

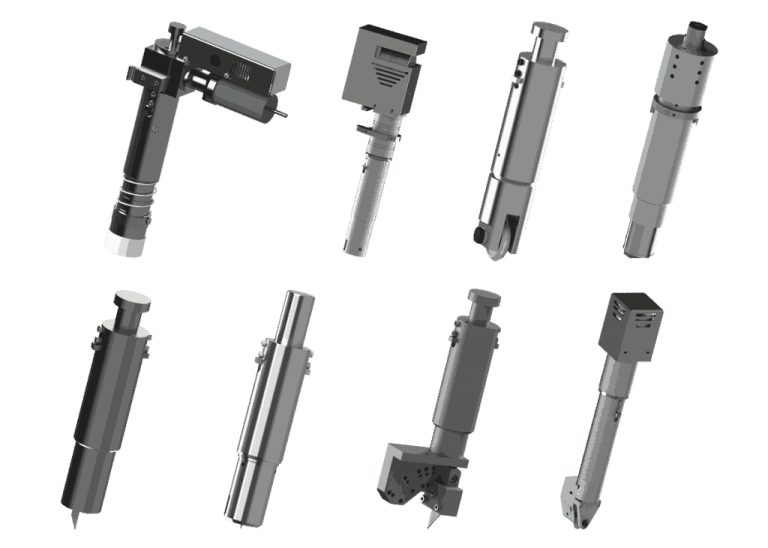

"Double decker" hd camera system

Two independent “Double Decker” camera groups, equipped with high-magnification lenses and dedicated LED lighting, with automatic focus. Views, checks, verifies and records all mounting jobs

“Anti curl” system

Plate “Anti Curl” System that allows used, curled plates to mounted with high accuracy by reducing and canceling plate deformities due to age and stretch, increasing the possibility the automatic application all but the worst plates

"Hands free" plate registration

Two Automated plate manipulation systems positions both single and multiple plates without table movement or operator involvement

Automatic plate application

It ensures a constant application pressure, guarantees a safe bond with the absence of distortions or air bubbles, for maximum standardization.

Automation

The automation system, managed via an easy to use touchscreen interface, guarantees the automatic positioning of all machine components for the highest precision.

Industry 4.0 ready

The machine software is designed for connection with company information systems and can be integrated into Industry 4.0.

OPTIONS:

Active skew control

Aligns & controls the plate during plate application.

Jūsu pateicības ziņojumu nevar nosūtīt

Zinot par atsauksmi

Ziņojums nosūtīts

Jūsu ziņojumu nevar nosūtīt

Uzraksti atsauksmi

Atsauksme nosūtīta

Jūsu atsauksmi nevar nosūtīt

Pick Up at our Shop/ stock in Riga:

Brīvibas gatve 204a ( entrance from Turaidas 2c)

Riga, LV-1039

Latvia

Standard Delivery:

Omniva Delivered within 2 - 5 days.

DPD

Express 1-2 Day Delivery *ask to manager

Next Day Delivery *ask to manager

Next Day Evening Delivery *ask to manager

Unlimited Delivery (VIP)

Sign up for VIP exclusive Free Delivery on all orders through the app for the whole year. Wanna unlock ALL the most exclusive VIP Benefits? *ask to manager

-------------------------------------------------

See DELIVERY Terms at: Delivery